วัสดุ

ซีลมาสเตอร์ใช้วัสดุ Premium grades คุณภาพสูงและดีที่สุดจากยุโรปเท่านั้น โดยมีขนาดหลากหลายและวัสดุชนิดต่าง ๆ มากกว่า 20 ชนิด โดยนำเข้าวัสดุใหม่อย่างสม่ำเสมอเพื่อให้เหมาะกับการกลึงซีลแต่ละขนาด ตอบสนองความต้องการใช้งาน ครบถ้วนพร้อมในสต๊อกมากที่สุดในประเทศไทย จึงทำให้ท่านลดต้นทุนในการผลิตมากยิ่งขึ้น วัสดุของเราเก็บไว้ในสต๊อคห้องปรับอากาศที่มีความเย็นตลอดวันเพื่อถนอมคุณสมบัติที่ดีของวัสดุก่อนการผลิต ซีลที่ได้จึงมีอายุการใช้งานยาวนาน

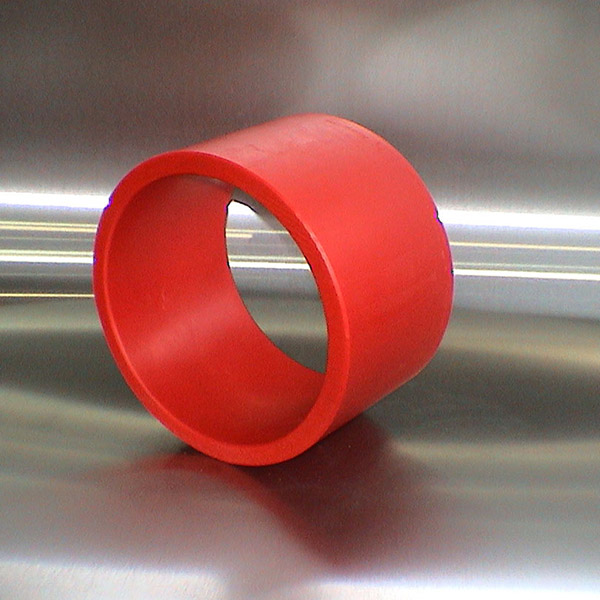

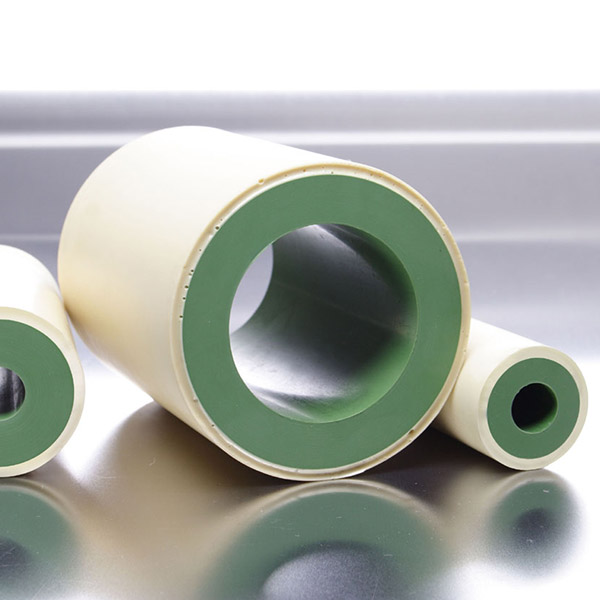

| HPU Thermoplastic Polyurethane |

|

HYDROLYSIS RESISTANCE. Extremely abrasion and extrusion resistant seals material. Easy mounting because of high elasticity. Hardness : 95 Shore A Temperature range : -20°C to +115°C Application : all standard hydraulic conditions. |

| FPM Fluorocarbon Rubber (Viton) |

|

Highly resistant to heat and chemicals Hardness : 85 Shore A Temperature range : -20°C to +220°C Application : all standard hydraulic conditions up to 250 bar. |

| C-HPU Thermoplastic Polyurethane |

|

HYDROLYSIS RESISTANCE. Offer a broader service range with similar mechanical properties as HPU. Hardness : 96 Shore A Temperature range : -37°C to +110°C Application : all standard hydraulic conditions. |

| EPDM Ethylene Propylene Diene Rubber |

|

Highly resistant to wheathering, ozone and ageing. Not resistant to mineral oils. Hardness : 85 Shore A Temperature range : -45°C to +150°C Application : hot water, steam and deluted acids. |

| C-HPU 55D Thermoplastic polyurethane |

|

High pressure and extrusion resistance. For high pressure seals and back up rings. Hardness : 55 Shore D Temperature range : -30°C to +110°C Application : all high pressure hydraulic application. |

| SILICONE MVQ |

| Highly resistant to wheathering, ozone and ageing. High electrical isolution. Hardness : 85 Shore A Temperature range : -60°C to +220°C Application : for static condition only. |

| C-HPU 72D |

|

Extremely high pressure and extrusion resistance. For high pressure seals application. Hardness : 72 Shore D Temperature range : -20°C to +110°C Application : all high pressure hydraulic application. |

| PTFE Virgin |

|

Resistant to almost all chemicals Hardness : 55 Shore D Temperature range : -200°C to +260°C Application : For use in food, chemical and medical industry. |

| NBR Nirtile Butadiene Rubber |

|

Abrasion resistant seals material. High elastic mean easy installation. Hardness : 85 Shore A Temperature range : -35°C to +120°C Application : all standard hydraulic conditions up to 250 bar. |

| PTFE D05 Filled with pigments |

|

Very good chemical resistance. Superior frictional properties with good wear characteristics. Hardness : 57 Shore D Temperature range : -200°C to +260°C Application : for high mechanical loads, suitable with all lubricating media. |

| H-NBR Hydrogenated Nirtile Butadiene Rubber |

|

Abrasion resistant seals material, compatible with compressor fluid R134A. Hardness : 85 Shore A Temperature range : -20°C to +150°C Application : all standard hydraulic conditions up to 250 bar. |

| PTFE D08 Filled with glass and pigments |

|

Very good wear resistance. Low friction properties. Hardness : 62 Shore D Temperature range : -200°C to +260°C Application : for medium mechanical loads in medium duty application. |

| PTFE GM Filled with glass and MoS2 |

|

Improved compression and wear resistance. Excellent chemical stability. Hardness : 58 Shore D Temperature range : -200°C to +260°C Application : Pneumatic, Hydraulic and mechanical parts. In dynamic seals application, where self lubricating properties. |

| PTFE D46 Filled with bronze and pigments |

|

Very good abrasion resistance. Excellent wear resistance and form stability. Hardness : 71 Shore D Temperature range : -200°C to +260°C Application : in hydraulics as bearings and seals for high duty and special items in industry. |

| PTFE Carbon Filled with carbon |

|

Good Chemical resistance. For average mechanical loads. Hardness : 67 Shore D Temperature range : -200°C to +260°C Application : in hydraulics system with water or water/oil emulsions and pneumatic system. Suitable for lubricated and non-lubricated conditions. |

| PTFE Ekonol Fill with ekonol |

|

Very good chemical resistance. Low friction and exellent wear resistance. Hardness : 63 Shore D Temperature range : -200°C to +260°C Application : for use in food and chemical industries. |

| PTFE Glass Filled with clean miled Glass Fibers |

|

Resistant to almost all chemicals. Low friction properties. Hardness : 60 Shore D Temperature range : -200°C to +260°C Application : for medium mechanical loads and for use in chemical industries. |

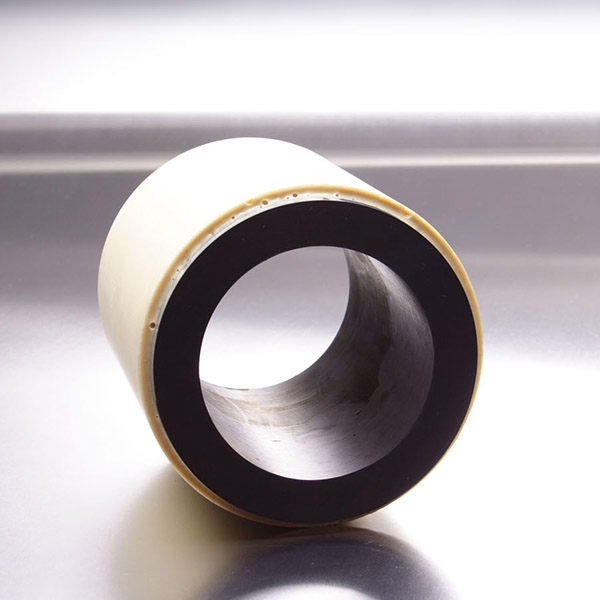

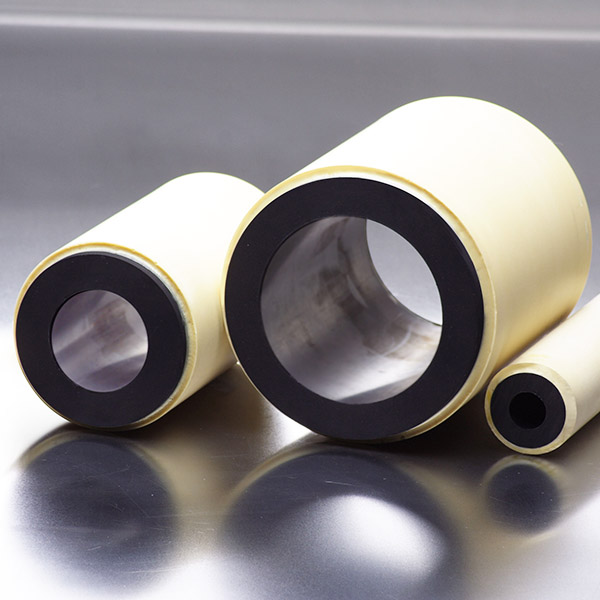

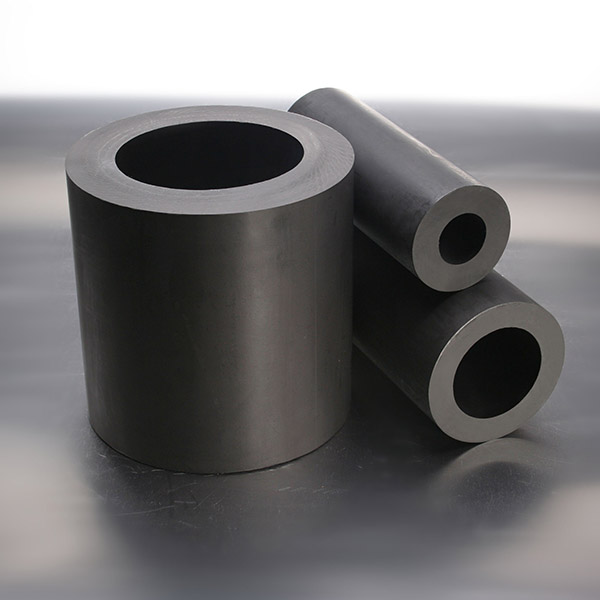

| POM Polyoxymethelene or Polyacetal |

|

High pressure and extrusion strength. Low water absorbtion. Hardness : 85 Shore D Temperature range : -45°C to +100°C Application : guide rings, back up rings. |

| PA Polyamide |

|

High pressure and extrusion strength. Hardness : 85 Shore D Temperature range : -40°C to +110°C Application : guide rings, back up rings. |

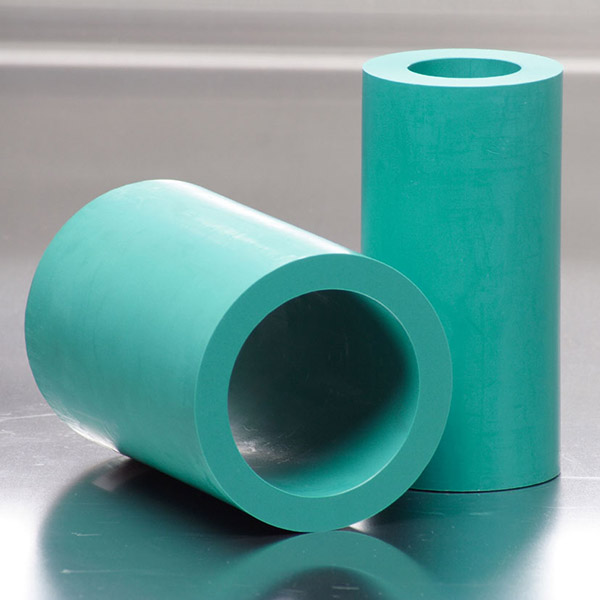

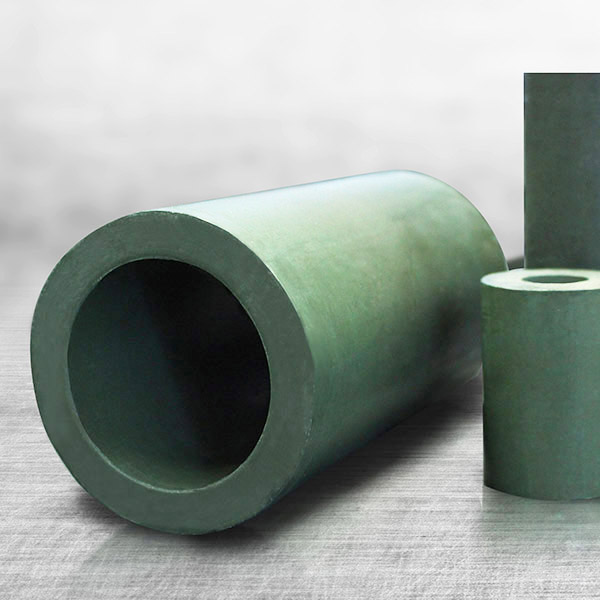

| UHMW-PE Polyethylene of ultra high molecular weight |

|

High resistance to abrasive were. Good corrosion resistance, good sliding and antiadhesive behavior. Hardness : 61 Shore D Temperature range : -200°C to +80°C Application : excellent chemical properties ; generally recognized as safe for foodstuff application. |

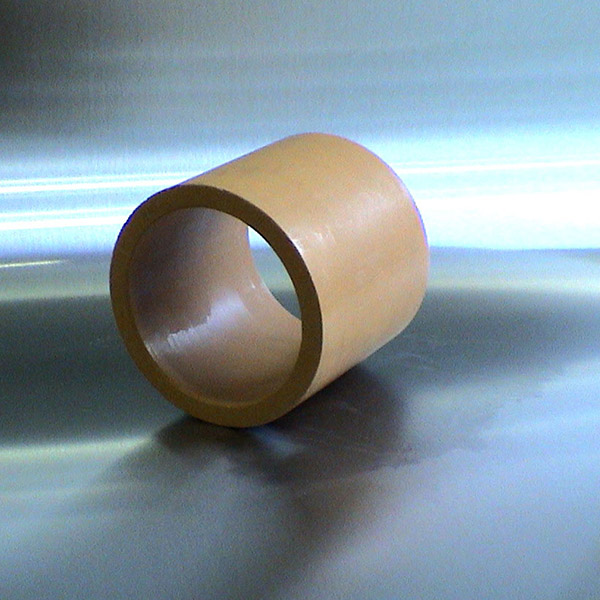

| Phenolic Resin |

|

High load sustainability, abrasion resistance and excellent dimensional stability. Hardness : 92 HRM Temperature range : -40°C to +180°C Application : guide rings and bushings. |