Materials

We selectively import high-end raw materials with varying sizes and over 20 material compounds from Europe to be produced into finished products by Seal-Master. All of our raw materials are kept in a temperature-controlled environment, which keeps the materials cool and saves them in perfect conditions before the manufacture dates. Therefore, you can count on our products to have better performance and longevity and help you save more in the long run.

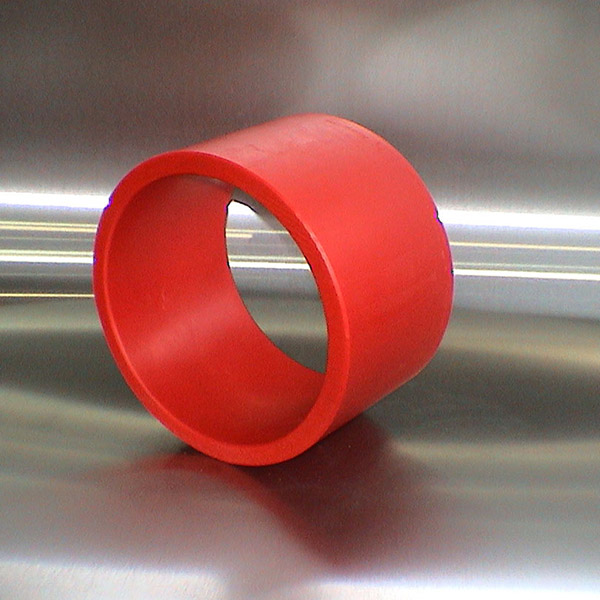

| HPU Thermoplastic Polyurethane |

|

HYDROLYSIS RESISTANCE. Extremely abrasion and extrusion resistant seals material. Easy mounting because of high elasticity. Hardness : 95 Shore A Temperature range : -20°C to +115°C Application : all standard hydraulic conditions. |

| FPM Fluorocarbon Rubber (Viton) |

|

Highly resistant to heat and chemicals Hardness : 85 Shore A Temperature range : -20°C to +220°C Application : all standard hydraulic conditions up to 250 bar. |

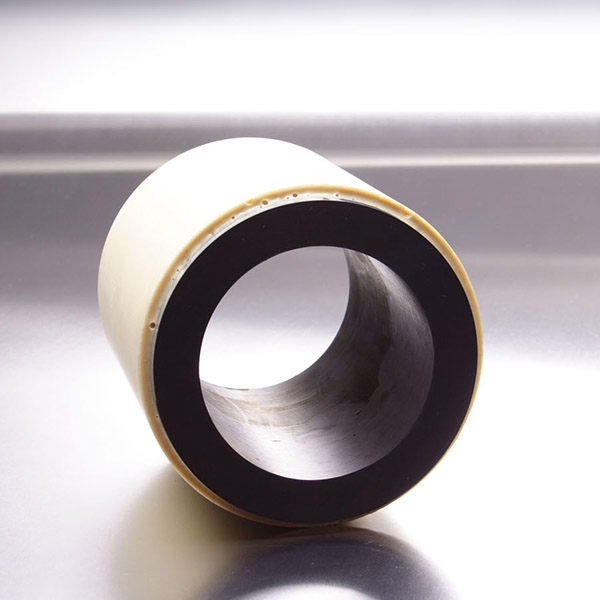

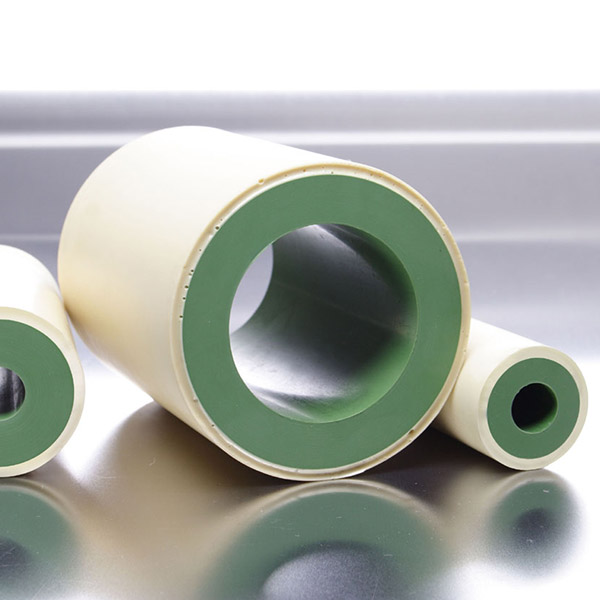

| C-HPU Thermoplastic Polyurethane |

|

HYDROLYSIS RESISTANCE. Offer a broader service range with similar mechanical properties as HPU. Hardness : 96 Shore A Temperature range : -37°C to +110°C Application : all standard hydraulic conditions. |

| EPDM Ethylene Propylene Diene Rubber |

|

Highly resistant to wheathering, ozone and ageing. Not resistant to mineral oils. Hardness : 85 Shore A Temperature range : -45°C to +150°C Application : hot water, steam and deluted acids. |

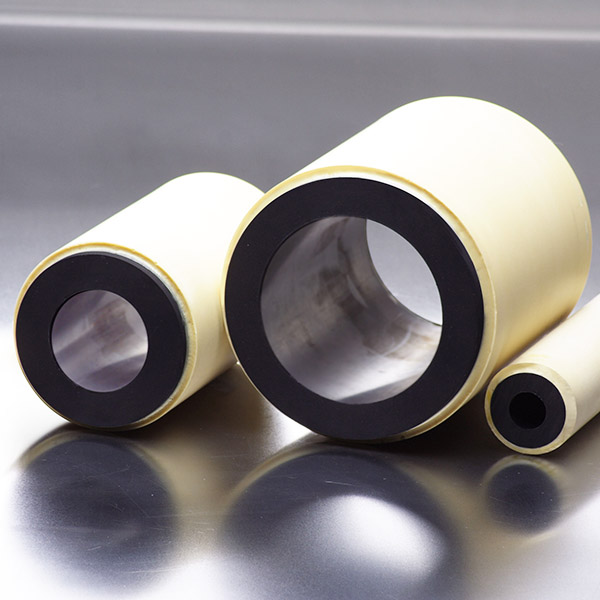

| C-HPU 55D Thermoplastic polyurethane |

|

High pressure and extrusion resistance. For high pressure seals and back up rings. Hardness : 55 Shore D Temperature range : -30°C to +110°C Application : all high pressure hydraulic application. |

| SILICONE MVQ |

| Highly resistant to wheathering, ozone and ageing. High electrical isolution. Hardness : 85 Shore A Temperature range : -60°C to +220°C Application : for static condition only. |

| C-HPU 72D |

|

Extremely high pressure and extrusion resistance. For high pressure seals application. Hardness : 72 Shore D Temperature range : -20°C to +110°C Application : all high pressure hydraulic application. |

| PTFE Virgin |

|

Resistant to almost all chemicals Hardness : 55 Shore D Temperature range : -200°C to +260°C Application : For use in food, chemical and medical industry. |

| NBR Nirtile Butadiene Rubber |

|

Abrasion resistant seals material. High elastic mean easy installation. Hardness : 85 Shore A Temperature range : -35°C to +120°C Application : all standard hydraulic conditions up to 250 bar. |

| PTFE D05 Filled with pigments |

|

Very good chemical resistance. Superior frictional properties with good wear characteristics. Hardness : 57 Shore D Temperature range : -200°C to +260°C Application : for high mechanical loads, suitable with all lubricating media. |

| H-NBR Hydrogenated Nirtile Butadiene Rubber |

|

Abrasion resistant seals material, compatible with compressor fluid R134A. Hardness : 85 Shore A Temperature range : -20°C to +150°C Application : all standard hydraulic conditions up to 250 bar. |

| PTFE D08 Filled with glass and pigments |

|

Very good wear resistance. Low friction properties. Hardness : 62 Shore D Temperature range : -200°C to +260°C Application : for medium mechanical loads in medium duty application. |

| PTFE GM Filled with glass and MoS2 |

|

Improved compression and wear resistance. Excellent chemical stability. Hardness : 58 Shore D Temperature range : -200°C to +260°C Application : Pneumatic, Hydraulic and mechanical parts. In dynamic seals application, where self lubricating properties. |

| PTFE D46 Filled with bronze and pigments |

|

Very good abrasion resistance. Excellent wear resistance and form stability. Hardness : 71 Shore D Temperature range : -200°C to +260°C Application : in hydraulics as bearings and seals for high duty and special items in industry. |

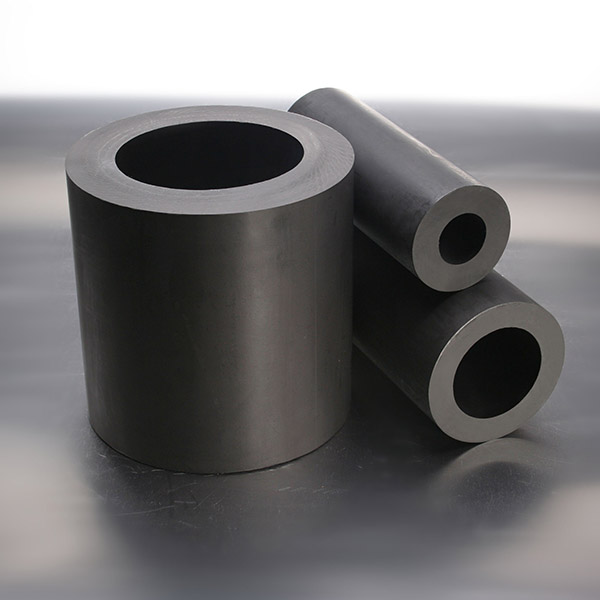

| PTFE Carbon Filled with carbon |

|

Good Chemical resistance. For average mechanical loads. Hardness : 67 Shore D Temperature range : -200°C to +260°C Application : in hydraulics system with water or water/oil emulsions and pneumatic system. Suitable for lubricated and non-lubricated conditions. |

| PTFE Ekonol Fill with ekonol |

|

Very good chemical resistance. Low friction and exellent wear resistance. Hardness : 63 Shore D Temperature range : -200°C to +260°C Application : for use in food and chemical industries. |

| PTFE Glass Filled with clean miled Glass Fibers |

|

Resistant to almost all chemicals. Low friction properties. Hardness : 60 Shore D Temperature range : -200°C to +260°C Application : for medium mechanical loads and for use in chemical industries. |

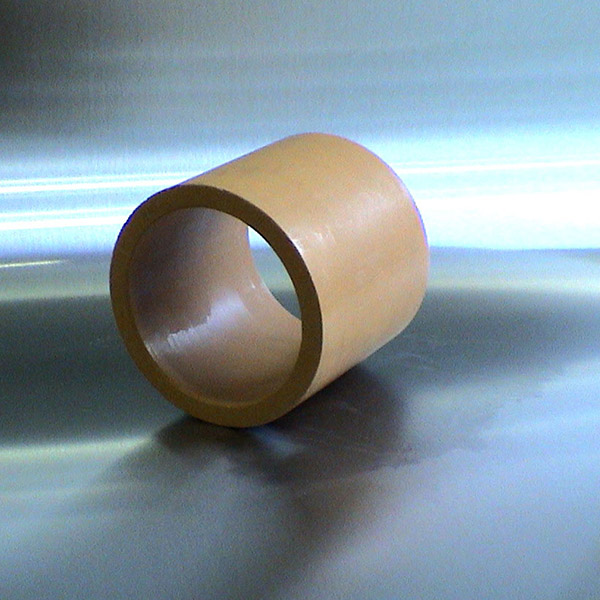

| POM Polyoxymethelene or Polyacetal |

|

High pressure and extrusion strength. Low water absorbtion. Hardness : 85 Shore D Temperature range : -45°C to +100°C Application : guide rings, back up rings. |

| PA Polyamide |

|

High pressure and extrusion strength. Hardness : 85 Shore D Temperature range : -40°C to +110°C Application : guide rings, back up rings. |

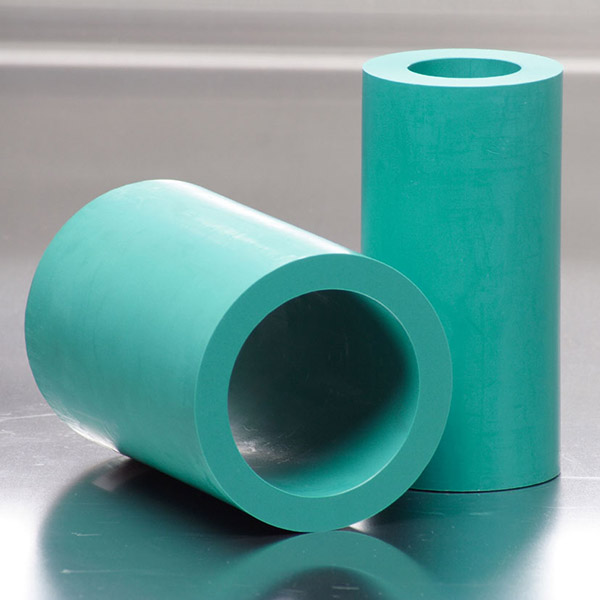

| UHMW-PE Polyethylene of ultra high molecular weight |

|

High resistance to abrasive were. Good corrosion resistance, good sliding and antiadhesive behavior. Hardness : 61 Shore D Temperature range : -200°C to +80°C Application : excellent chemical properties ; generally recognized as safe for foodstuff application. |

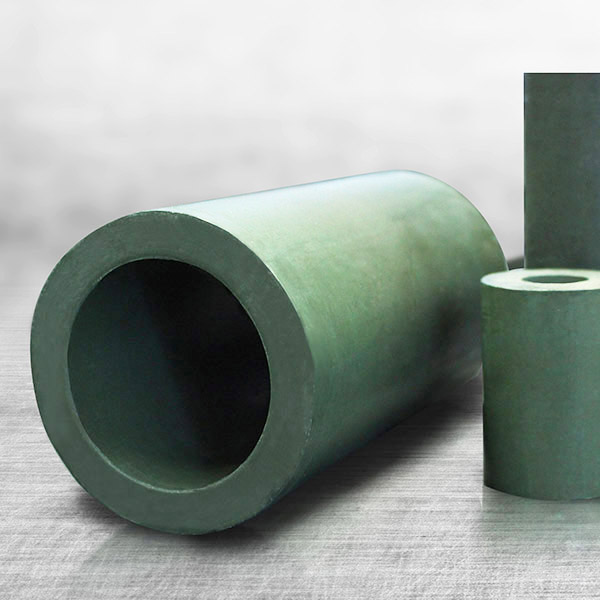

| Phenolic Resin |

|

High load sustainability, abrasion resistance and excellent dimensional stability. Hardness : 92 HRM Temperature range : -40°C to +180°C Application : guide rings and bushings. |